Measure me this...

So we know we want to do this, we know why water works and we've even looked at what we can buy. Can we spend some money yet?! Well....no. Not quite yet, anyway. First, it's important to know what all those little facts and figures are for some of this equipment we just looked up.First, there are some crucial measurements that need to be discussed. Water cooling is not all plug-and-play, and (like many things on a computer), you can't just go mix and match anything that you feel like and expect it to work. There are a host of different "sizes" of things, but there are two that are absolutely crucial to basic system assembly - hose and barb size.

You're hosed

What does vary considerably in the water cooling world is hose size - and it is important to know the size that your setup is best with. Different water blocks cool better with different hose diameters and flow rates (which are greatly limited by the hose), so one size does not fit all - either literally or figuratively.

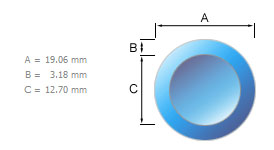

Hoses have three main measurements, but

only one is really important to us.

Though it seems like a lot of numbers, it's really pretty simple - just remember that the ID of your hose equals the OD of your barbs. The only place this isn't true is with the PtC fittings, which will be labeled simply 10mm/8mm or 8mm/6mm - the same as the hose.

Flow-er power

With the measurements out of the way, let's discuss two new figures - flow rate and pressure. Though the two seem at first like they are very similar, that's actually not at all true.Flow rate (measured in Litres per minute or Gallons per minute, usually) describes how much water (note that we're talking about a specific fluid - this is important) the system moves over a period of time. In a closed loop system, such as a water cooling setup, this translates to how many times the fluid will go around the loop. This is important, because each trip around means a trip both through the water block and through the radiator. Flow rates are the "constant" in the system - the pump will always move that much water as long as there is sufficient pressure in the line to move it.

The Laing D5 pump features a

variable flow rate, perfect for block

testing.

Pressure, on the other hand, is the variable figure illustrating how much force that flowing water exerts (usually measured in PSI). Pressure is an odd animal in water cooling, because it is good in some respects, but bad in others. See, in order to exert force, there has to be something to exert against - which means that pressure is really the measurement of resistance able to be overcome in a water cooling loop. To this effect, water blocks will usually have a "pressure drop" measurement, explaining exactly how much they decrease the pressure from one side of the block to the other.

These two concepts of flow rate and pressure lead to how pumps are measured - flow rate, measured in GPM or LPM, and head pressure, usually measured in feet or metres. Flow rate is exactly as above, but head pressure is not quite what it seems - It means that this pump will create a vertical stream of water (known as a head) that is X feet high. If we translated that into a measure of pressure, such as bars or PSI (many pumps now list this figure also), you would have the theoretical maximum level of pressure in the system, assuming the pump had a constant supply of water and power (which, one hopes, it would).

Flow rate and pressure can be further manipulated, as they have an inverse relationship - but that is beyond the scope of this article. Instead, we'll move onto the "enemy" of water cooling....

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.